Sentinel software is a high-performance tool for artificial vision solutions, with a strong focus on solving problems in production processes. Save time implementing new processes and raise the quality level of your products.

Inspection Systems

Inspection of Injected Parts

With great adaptability to the natural variations of injected plastic parts, this inspection solution evaluates shapes and shades to ensure the complete integrity of the part according to quality criteria.

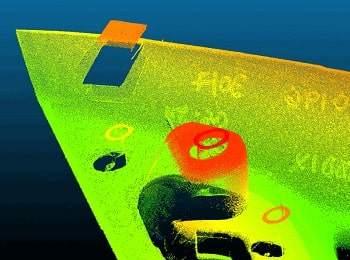

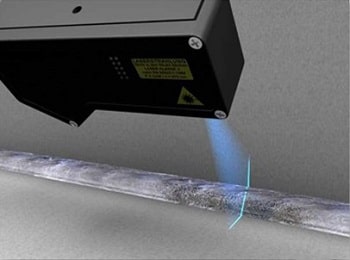

3D Weld Inspection

The 3D weld inspection system can detect defects with a minimum dimension of 0.1mm in just 3 seconds. Each inspection evaluates the weld’s shape, color, size, and texture.

Robot Guidance

Picking solutions are increasingly common in component picking processes. We have a competitive solution with 2D or 3D technology, capable of speeding up production and with a very short payback.

Quality as a decisive factor in Industry 4.0

With strong market competition, product quality is a decisive factor in maintaining and conquering new customers. The focus on production automation ensures process repeatability while machine vision ensures product quality. Machine vision solutions detect production defects, allow automatic robot guidance in the production process or perform highly accurate measurements of product components. In the automotive, pharmaceutical, or metalworking industries, you can mitigate errors and transform your production process into a controlled process, focusing on product quality.

Our Customers

Partners